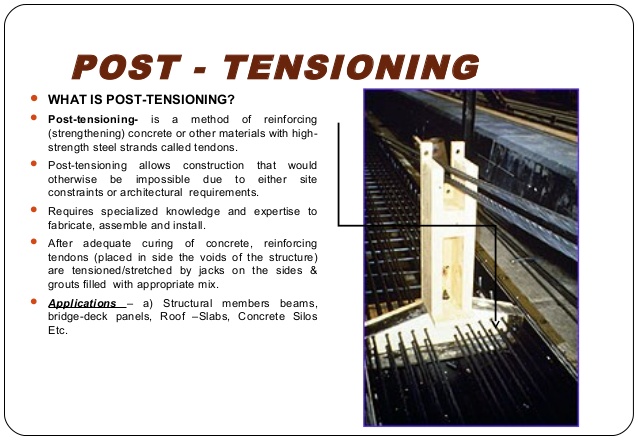

Post tensioning – Advantages and applications

Post-tensioning is a very effecting method of reinforcing (fortifying) concrete or other materials with high-strength steel strands or bars, generally called as tendons. The tendons stand for prestressing steel cables within plastic ducts or sleeves and they are arranged in the forms prior to placement of the concrete.

The tension is employed to the tendons once the hardening of the concrete is completed. Least grade of concrete applied is 30 Mpa.

Ducts are set in this type of prestressing.

In post tensioning method, the tendons are positioned in ducts as soon as the casting of concrete is completed.

The duct resists bond among concrete and the tendons while the tensioning is goining.

Contrary to pre-tensioning, the tendons are extracted with the reaction acting against the hardened concrete.

When the arranged ducts are grouted, then it is known as bonded post-tensioning.

And when the ducts are not grouted then it is known as unbonded post-tensioning. Tendon is retained in place with end anchorages.

Given below, the different phases of post tensioning :-

- Casting of concrete

- Positioning of the tendons

- Positioning of the anchorage block and jack

- Using tension to the tendons

- Seating of the wedges

- Cutting of the tendons

The following benefits are obtained from post-tensioning :-

- Post-tensioning is very effective for heavy cast-in-place members.

- The waiting period in the casting bed is minor.

- The transmission of prestress does not depend on transmission length.

- Less floor to floor height.

- Elevated column-free space.

- Minimized weight and load withstanding systems.

- Uncomplicated Slab design and construction.

- Superior deflection control & crack control.

- Curtailment in foundation loads in 2-3 times.

Application of post tensioning system :-

High Building

- Reduced weight & slab thickness.

- Increased number of floors with similar building height.

- Fast construction process.

Parking

- Reduced weight.

- Perfect use of space.

- Water-resistance slabs (except cracks).

- Reduced slab thickness.

- Rapid construction process

The following equipments are required for post-tensioning :-

- Casting bed

- Mould/Shuttering

- Ducts

- Anchoring devices

- Jacks

- Couplers (optional)

- Group equipment (optional)