Geopolymer concrete - Uses and benefits

Geopolymer concrete is a ground-breaking and sustainable construction material. It can be used in place of portland cement concrete to reduce the adverse effect of extreme CO2 emission.

Geopolymer cement concrete is produced with various waste materials like fly ash and ground granulated blast furnace slag(GGBS). Fly ash is a debris that is mostly used in thermal power plant and ground granulate blast furnace slag is applied as debris in steel plant.

With the use of exact methodology, both fly ash and GGBS are refined and utilized for concrete works in the type of geopolymer concrete. This type of concrete helps in minimizing the stock of wastes.

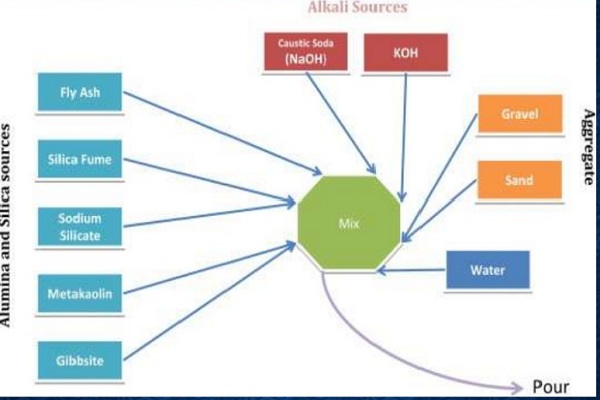

The prime ingredients of geopolymers are silicon and aluminium produced with thermally operated natural materials (namely kaolinite) or industrial byproducts (e.g. fly ash or slab) and an alkaline driving solution which hydrates these materials into molecular chains and networks to develop solidified binder. It is also defined as alkali-activated cement or inorganic polymer cement.

Composition of Geopolymer Concrete

This type of concrete is formed with the following materials:

- Fly ash – A byproduct of thermal power plant

- GGBS – A byproduct of steel plant

- Fine aggregates and coarse aggregates as necessary for normal concrete.

Alkaline activator solution for GPCC as described above. Catalytic liquid system is employed as alkaline activator solution. To develop this concrete, solutions of alkali silicates and hydroxides as well as distilled water are combined. The purpose of alkaline activator solution is to drive the geopolymeric source materials having Si and Al like fly ash and GGBS.

Characteristics of Geopolymer Concrete

Compressive strength of geopolymer concrete is up to 70 MPa (N/mm2). The concrete obtains its compressive strength quickly as compared to ordinary Portland cement concrete.

The concrete strength after 24 hours becomes over 25 MPa. Compressive strength after 28 days becomes 60 to 70 MPa.

Some other useful features of Geopolymer Concrete

- The drying shrinkage is very low with regard to cement concrete. Thus, it becomes applicable for thick and greatly constrained concrete structural members.

- It contains low heat of hydration relating to cement concrete.

- The fire resistance capacity is significantly superior as compared to OPC based concrete (up to 2400 degree F)

- According to ASTM 1202C, this concrete contains chloride permeability rating of ‘low’ to ‘very low’. It can provide greater safety to reinforcement steel against corrosion with regard to conventional cement concrete.

- This concrete has extreme acid resistance capacity while being examined under exposure to 2% and 10% sulphuric acids.

- It has superior corrosion resistance.

- It has extreme compressive & tensile strengths

Uses of Geopolymer Concrete

- This concrete is suitable for building up pavements, retaining walls, water tanks as well as precast concrete products like bridge decks, railway sleepers, electric power poles, parking tiles.

- Marine structures because of resistance capacity for chemical attacks.

- Waste containments (fly ash)

- Lately, geopolymer concrete is used in the construction of The University of Queensland’s Global Change Institute (GCI).