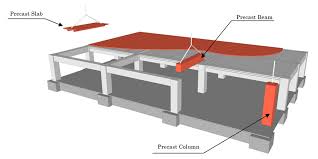

Precast Concrete Construction Details

Benefits of precast concrete construction

- Speed of construction is very fast

- Superior quality control

- Whole building can be precast-walls, floors, beams etc.

- Fast onsite construction

- Controlled conditions in the factory leads to superior quality

- As prestressing can be executed simply, it can decrease the size & number of the structural members

Application areas :-

- Concrete curtain walls

- As an external cladding (it may contain exposed aggregate)

- For structural walls

- With the power to precast in three dimensions, it facilitates precast panels to build up parts of mechanical systems

- Controlled conditions in the factory leads to superior quality

Slabs

- Density of 4", 6" & 8"

- Extent up to 25' - 0"

- Standard panel width = 4'-0"

- Standard designations = FS4 (FS = Flat slab; 4 = thickness of slab in inches)

Hollow core slab

- Density of 4", 6", 8", 10" and 12"

- Extent up to 40' - 0"

- Standard panel width = 4'-0"

- Standard designations = 4HC6 (4 = panel width in feet, HC = Hollow Core, 6 = slab

- density in inches)

Beams

Rectangular Beam (RB)

- Density of 4", 6", 8", 10" and 12"

- Extent up to 40' - 0"

- Standard panel width = 4'-0"

- Standard designations = 4HC6 (4 = panel width in feet, HC = Hollow Core, 6 = slab

- density in inches)

L and IT (inverted tee) beams (LB and IT)

- Generally utilized to provide to support slabs, walls, masonry and beams

- Standard beam width = 12"

- Depths of 20", 28", 36", 44", 52" and 60"

To learn the detail precast concrete construction phase, go through the following video tutorial

Video Source : Nitterhouse Concrete Products